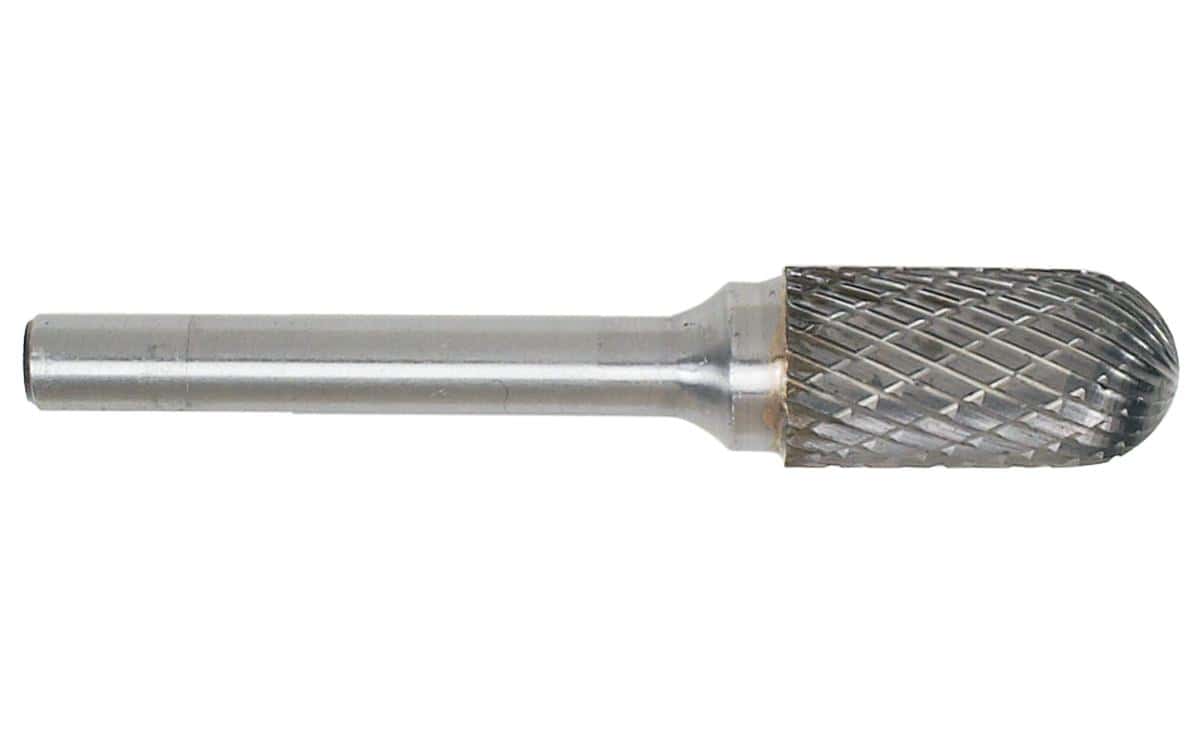

When you have a tough grinding job that requires more precision than a grinding wheel and more aggression than a hand file, the Walter 01V039 SC-2 Double Cut Carbide Burr is your go-to solution. Built for welders and fabricators who need to get the job done fast, this heavy-duty tungsten carbide burr is designed to eat through steel and stainless steel with ease. The SC-2 shape features a cylindrical body with a rounded nose, giving you the flexibility to grind flat surfaces, smooth out inside corners, and blend welds seamlessly without changing tools.

Why choose a Double Cut burr? It's all about speed and control. The cross-cut tooth pattern creates smaller chips, which prevents the burr from loading up and allows for faster stock removal. It also reduces the "pulling" action often felt with single-cut burrs, making the tool much easier to control. This means you can grind longer with less fatigue and get a smoother finish right out of the gate. Whether you are enlarging a bolt hole that didn't quite line up or cleaning up a messy weld bead, this burr gives you the control you need to make precise corrections quickly.

Walter Surface Technologies is known for making tools that last, and this carbide burr is no exception. The high-grade tungsten carbide construction ensures the teeth stay sharp job after job, saving you money on replacements. Poorly made burrs can vibrate and chatter, ruining your workpiece and wearing out your grinder. Walter burrs are perfectly balanced to run smooth and true, protecting your equipment and your hands. Add the 01V039 to your toolbox today and experience the difference that professional-grade abrasives make in your daily fabrication work.

| Additional Information |

|---|

| Brand:Walter Surface Technologies |

| Used To Grind:Steel or Stainless |

| Shape Code:SC-2 |

| Cut Type:Double Cut |

| Material:Tungsten Carbide |

| Shape Description:Cylindrical Radius End |

| Packaging Description:1 per each |