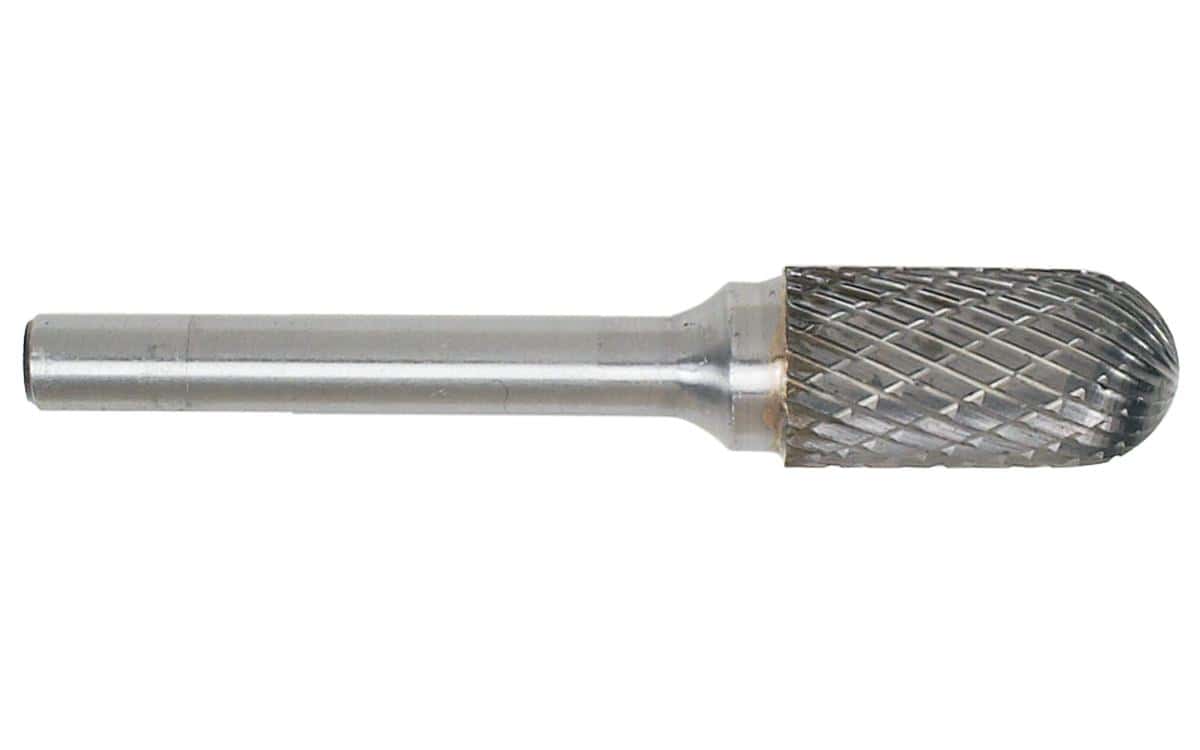

When you are in the middle of a fabrication job, you need tools that bite. The Walter SC-4 Double Cut Carbide Burr (01V040) is built for welders who demand speed and control when cleaning up welds or prepping metal. This isn't just another rotary file; it is a high-performance tungsten carbide tool designed to eat through tough materials like stainless steel and mild steel without bogging down. If you use a die grinder daily, you know that balance is everything. Walter has engineered this burr with impeccable concentricity, meaning it spins true without the annoying wobble that kills your bearings and numbs your hands.

The "Double Cut" feature is a game-changer for efficiency. The cross-cut flutes work together to pulverize metal into tiny chips rather than long, dangerous slivers. This allows for rapid stock removal while leaving a smoother finish than a standard single-cut burr. It also makes the tool much easier to control, preventing it from "climbing" or jumping out of the cut, which is critical when you are doing detailed work or enlarging holes in tight spaces. The SC-4 shape (cylindrical with a ball nose) is particularly useful for grinding out fillet welds or blending contours where a sharp corner would dig in.

Whether you are deburring a fresh cut, smoothing out a heavy weld bead, or enlarging a bolt hole that is just a hair too small, this Walter carbide burr is the reliable partner you need in your toolbox. It is tough enough to handle the heat of aggressive grinding and stays sharp long after cheaper bits have dulled. Upgrade your die grinder setup with a burr that works as hard as you do.

| Additional Information |

|---|

| Brand:Walter Surface Technologies |

| Used To Grind:Steel or Stainless |

| Item:Carbide Burr |

| Shape:SC-4, Cylindrical with Radius End |

| Cut Type:Double Cut |

| Material:Tungsten Carbide |

| Shank Diameter:1/4" |

| Packaging Description:1 per each |