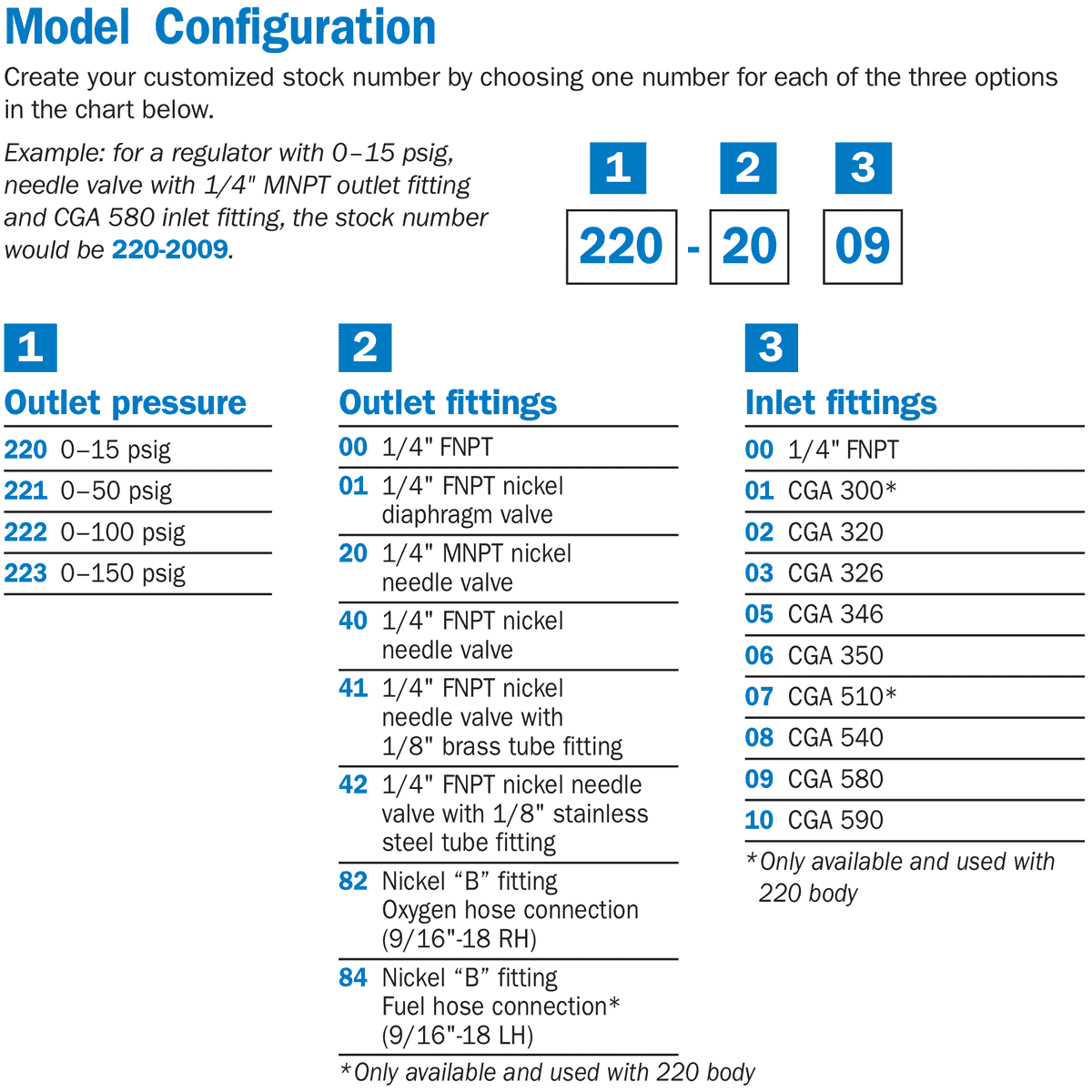

When your work demands more than just standard industrial gas control, the Miller Smith 222-42-10 Silverline Regulator steps up to the plate. While built with the precision required for laboratory use, this regulator retains the rugged durability that Miller Smith equipment is known for. It is the ideal solution for welders and tradespeople who occasionally interface with specialty gases or require high-precision pressure control for specific fabrication or testing processes involving CGA 590 gases.

The primary advantage of this two-stage regulator is its ability to provide unwavering pressure control. Standard single-stage regulators often suffer from "decay," where the outlet pressure rises as the tank pressure falls. The 222-42-10 eliminates this issue completely. Whether your cylinder is full at 3500 PSI or nearing empty, your output remains locked at your set point (up to 100 PSI). This consistency is critical for specialized TIG welding applications, purging, or leak testing where pressure variations can ruin a job.

Don't let the "High Purity" label fool you—this regulator is built to last. The construction features rugged brass bar stock that has been plated for extra protection against the bumps and scrapes of shop life. The gauges are large and easy to read, reducing eye strain when you are checking levels from across the bench. The stainless steel diaphragm adds a layer of reliability that standard diaphragms can't match, resisting fatigue and ensuring the regulator holds its settings over years of service.

Equipped with a CGA 590 inlet, this regulator is ready to connect to cylinders containing Industrial Air or Sulfur Hexafluoride. The outlet features a precise 1/8" tube stainless steel needle valve, giving you fine-tuned control over flow rates right at the source. Whether you are setting up a specialized purge chamber or running pneumatic testing equipment, the Miller Smith 222-42-10 delivers the performance you need with the reliability you expect from a top-tier brand.

| Additional Information |

|---|

| Brand:Smith Equipment, Miller |

| Series:Silverline 220 |

| Gas Service:Specialty Gas, Industrial Air, Sulfur Hexafluoride |

| Stage Type:Two Stage |

| Inlet Connection:CGA 590 |

| Delivery Pressure Range:0-100 PSIG |

| Max Inlet Pressure:3500 PSIG |

| Body Material:Plated Brass Bar Stock |

| Diaphragm Material:Stainless Steel |

| Gauge Size:2-1/2 Inch |

| Outlet Connection:1/8" Tube Fitting, Needle Valve |

| Application:Gas Chromatography, High Purity Analytical |

| Packaging Description:1 per ea |