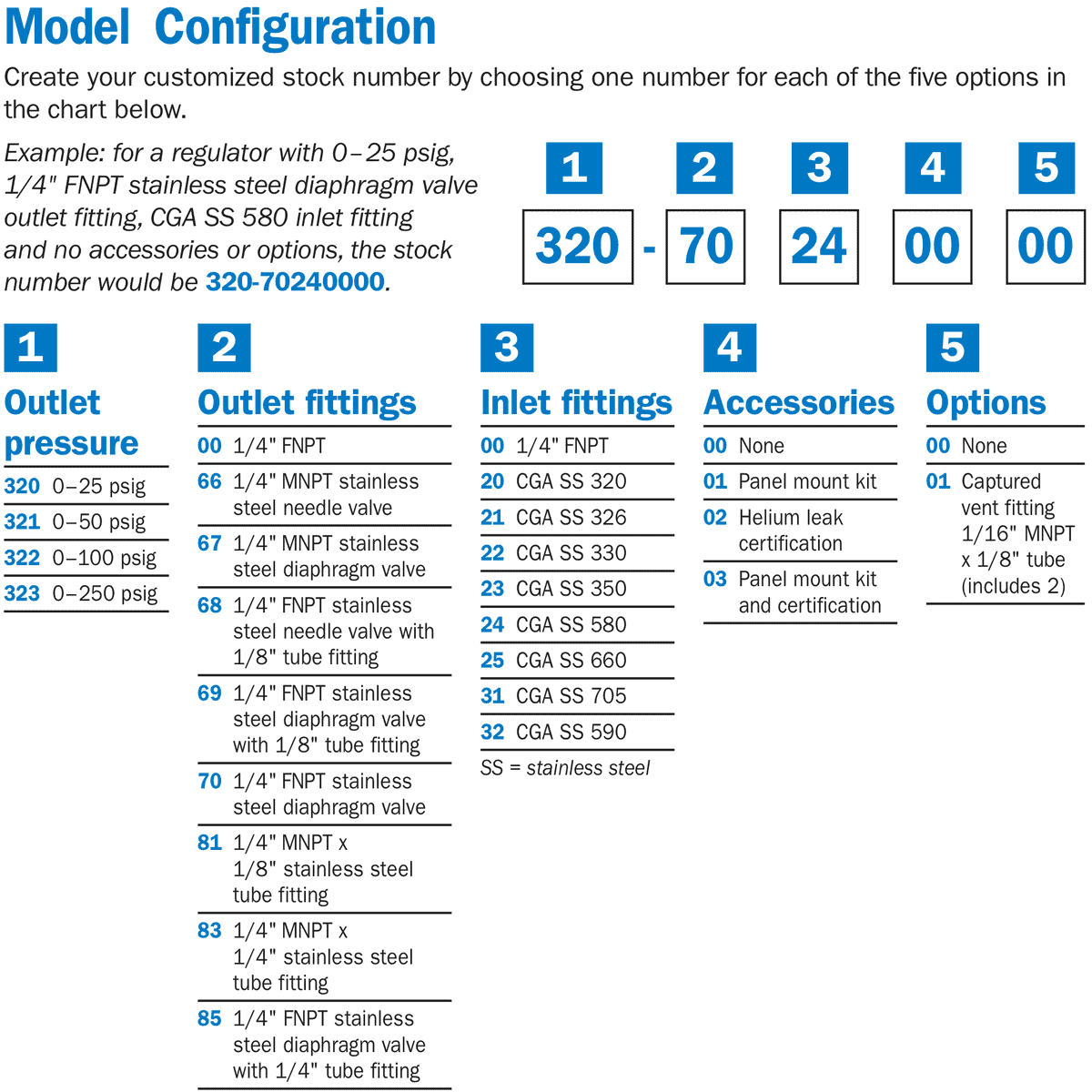

Welders Supply is proud to offer the Miller Smith 320-70-20-00-00, a premium two-stage regulator designed for high-purity and corrosive gas applications. When precision cannot be compromised, this stainless steel regulator delivers consistent pressure control and exceptional durability. Equipped with a CGA 320 connection, it is optimized for use with Carbon Dioxide and other compatible gases where a clean, non-reactive flow path is required. With a delivery range of 0-25 PSI, it provides fine low-pressure control suitable for sensitive industrial and laboratory equipment.

Durability meets purity in the 320 Series. The regulator body is machined from 316 stainless steel bar stock, providing a rugged housing that withstands harsh industrial environments and corrosive media. Unlike brass regulators, this stainless steel unit prevents internal oxidation and contamination, ensuring that your process gas remains as pure as the source. The internal wetted parts, including the diaphragm and filtered seat, are also crafted from 316 stainless steel and PCTFE, ensuring broad chemical compatibility and long-term reliability.

The two-stage design of this regulator steps down cylinder pressure in two phases, resulting in an extremely stable outlet pressure that does not drift as the cylinder empties. This "decay-free" performance is essential for automated welding processes, laser cutting, and analytical testing where pressure spikes could ruin a workpiece or invalidate a test. Safety is paramount; the regulator features a captured vent port in the bonnet to safely divert gases if necessary, and the metal-to-metal diaphragm seal ensures the highest level of leak integrity available.

Invest in the Miller Smith 320 Series for your critical gas delivery needs and experience the difference that professional-grade high-purity equipment makes.

| Additional Information |

|---|

| Brand:Smith Equipment |

| Gas Service:Carbon Dioxide (CO2), Specialty Gas, Corrosive Gas |

| Material:316 Stainless Steel |

| Stages:Two Stage |

| Inlet Connection:CGA 320 |

| Delivery Pressure Range:0-25 PSIG |

| Series:320 Silverline |

| Max Inlet Pressure:3500 PSIG |

| Diaphragm Material:Convoluted Stainless Steel |

| Seat Material:PCTFE |

| Port Size:1/4" FNPT |

| Gauge Size:2-1/2" |

| Packaging Description:1 per ea |