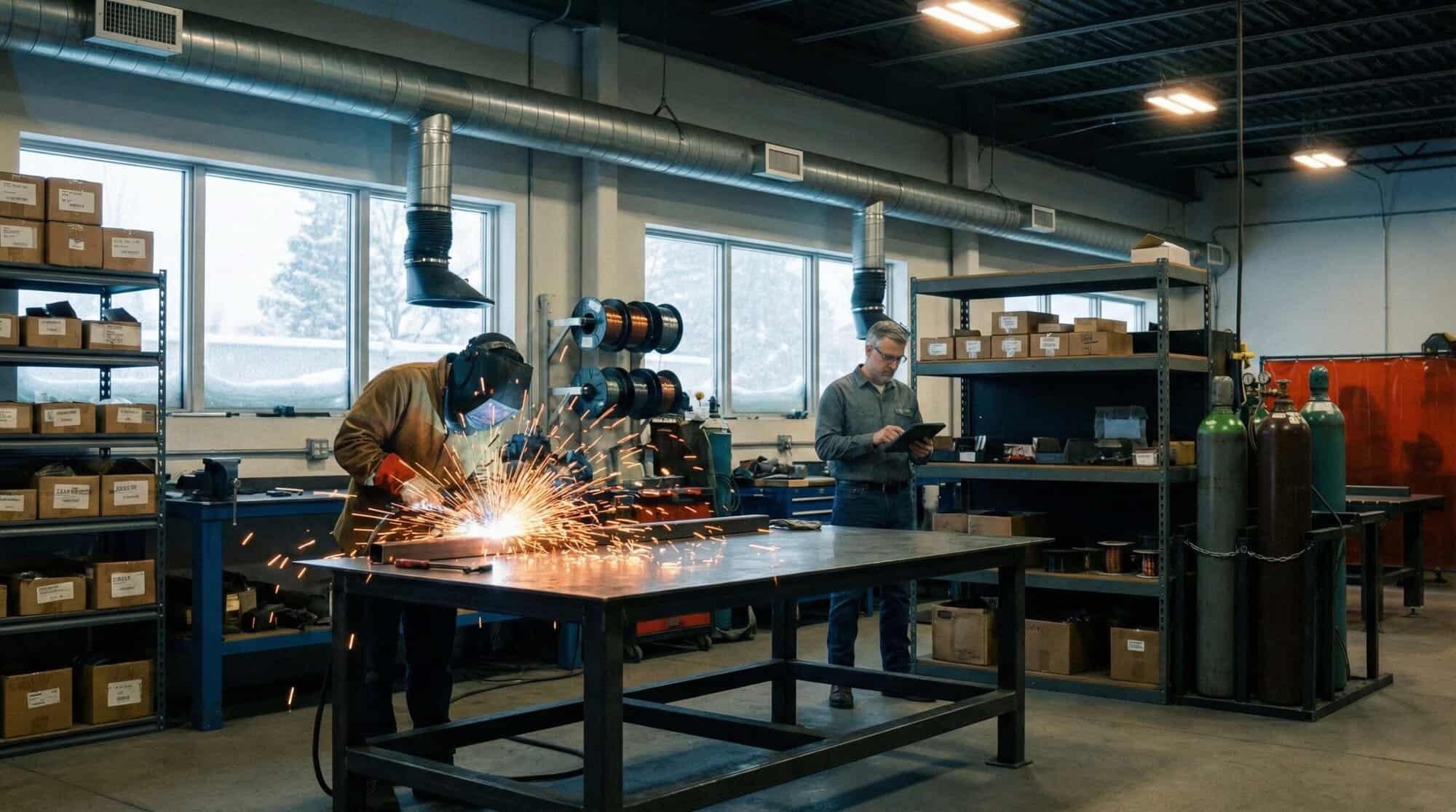

What Winter Really Looks Like Inside a Welding Shop

December 17, 2025 3:41 pm

Winter feels different inside a welding shop. The welders are still working, the sparks still fly, but the pace shifts just enough for managers to step back and look at the bigger picture, consumables, ventilation, equipment, workflow, and planning for next year’s projects.

December tends to be the month when welding consumables get counted, cylinders are inspected, and shops pay attention to supplies that either ran out too fast or didn’t move at all. Across the industry, many managers see the same end-of-year pattern: fast-turning consumables that need better tracking, leftover stock from mid-year orders, and a clear opportunity to tighten inventory before January’s workload returns.

Industry conversations and end of year planning across the welding world tend to focus on a few smart priorities as December arrives and shops prepare for the year ahead. At WeldersHelper.com, we are built to support those priorities with deep inventory, competitive pricing, and fast reliable fulfillment.

- Get consumable inventory dialed in

Year end counts of welding wire, electrodes, filler metals, nozzles, and PPE help shops avoid the January scramble. With consumable demand continuing to rise across fabrication and manufacturing, having the right products on hand matters more than ever.

WeldersHelper.com carries a wide selection of trusted consumables at strong prices, with fast shipping to keep your shop stocked and moving without disruption.

- Double check ventilation and fume control for winter

Cold weather changes airflow inside fabrication spaces, which makes winter a key time to review fume extraction and respiratory protection. From fume management accessories to PPE essentials, WeldersHelper.com keeps the products shops rely on readily available so safety stays front and center as temperatures drop.

- Remove small workflow bottlenecks

December often exposes minor inefficiencies such as tool access, cable management, shared stations, or outdated processes that quietly affect productivity. Having the right tools, consumables, and shop supplies readily available can make a real difference. Our broad inventory helps shops quickly replace, upgrade, or replenish what may be slowing them down.

- Prepare for material and process trends shaping next year

Flux cored wire growth, increased automation, mixed material fabrication, and higher deposition demands are shaping how shops operate. December is an ideal checkpoint to assess what consumables and equipment will be needed in the months ahead. WeldersHelper.com is well equipped with the products and pricing to support these evolving needs without long lead times or inflated costs. Don’t forget to check out specials and rebates on our website.

Across welding forums, supplier insights, and industry forecasts, one message comes through clearly. The shops that use December wisely perform better in the year ahead. Not by overhauling everything, but by paying attention to inventory, safety, workflow, and changing material demands. December is a strategic month, and WeldersHelper.com is ready with the inventory, pricing, and support to help welding shops start the new year stocked, prepared, and confident.